Product |

|

|

| |

|

|

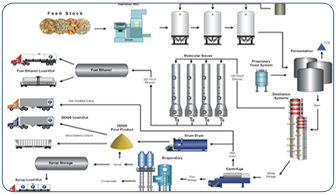

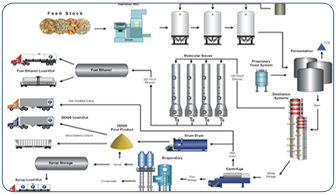

Manufacturer of Grain Based, Distillation Process and Dehydration Processes in India |

|

|

| |

|

|

Fermentation |

|

Our Fermentation system

design based on crucial parameters which helps to reduce loses

of alcohol in fermentors and increase the yeild of alcohol

by controlling the unwanted byproducts. |

|

|

Fermentation systems for alcohol

production are designed to handle a verity of feed stock. |

|

|

Sugarcane juice streams (primary, secondary,

mixed, syrup, filtrate etc.) |

|

|

Cane Molasses |

|

|

Grains, (Wheat, Rice, Corn, Millet, Sorghum,

Rye, Bajra etc.) |

| |

|

|

|

|

| |

|

|

| Features |

|

|

High Fermentation efficiency |

|

|

Minimal wastewater generation |

|

|

Yeast separation and recycle under gravity,

eliminating need for expensive yeast separators. |

|

|

Flexibility to operate continuous as well

as syncronised mode of operations, depending on characteristics

of feed stock. |

|

|

Rugged operation |

|

|

Provision to tap high purity CO2 |

|

|

|

| |

|

|

Distillation Process |

|

We offer separation

technologies with higher efficient multiple distillation column

systems. Which operate at lower energy consumption, Higher yield.

|

| |

|

|

Features |

|

|

Multi product distillation systems. |

|

|

Low energy consumption. |

|

|

State of art in plant automation. |

|

|

Consistency in product quality. |

|

|

Minimum shutdown. |

|

| |

|

|

Dehydration Processes |

|

| Molecular sieve dehydration plant design

based on pressure swing adsorption with thermal heating to maintain

quality norms with advantages. Raj Distillery is a leading manufacurer

and supplier of fuerl ethanol plants,distillation process plants and

dehydration process plants. |

| |

|

|

|

High Ethanol Dryness. |

|

|

Lower Energy Consumption. |

|

|

Higher desiccant (Molecular Sieve) life. |

|

| |

|

|

| Zero Liquid Discharge |

|

|

RAJ Zero liquid

Discharge Technology provide the most comprehensive, cost-effective

and reliable operating systems and services. These products

and services are designed to help keep your plant safe, or

your company profitable. |

|

| The Evaporation

System consists of single or multiple calendrias (Tubular

shell and tube heat exchangers) followed by drying systems.

Evaporation systems are designed with consideration of higher

fouling fluids, rugged operation, less maintenance and operating

cost, easily stable with fluctuation on steam or feed side.

For drying we offer rotary and spary dryer considering the

suitability and nature of the product to be handle. The dryers

are highly efficient having low operating costs and easy to

operate. These dryers are highly effective for products, which

required gentle drying and higher residence time. |

|

| |

|

|

Features of Evaporation Systems |

|

|

Enhance water and waste minimization. |

|

|

|

Operated under vacuum or pressure. |

|

|

Fully automated systems to ensure consistent

product quality. |

|

|

Process fluids with higher viscosities and also

be handled effectively. |

|

|

No loss in production time. |

|

|

Comparatively less maintenance and operating

cost. |

|

| |

Features of Drying Systems |

|

|

| |

|

|

Services |

|

|

|

|

Turnkey Plants |

|

|

Manufacture & supply of Equipments |

|

|

Engineering and Supervision of Civil, Structural |

|

|

Process and detailed Engineering. |

|

|

Project Management |

|

|

Commissioning and Training |

|

|

After sales support |

|

| |

|

|

|